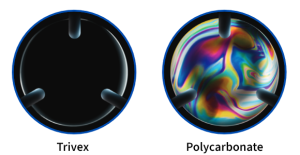

One of the most important decisions you will make when setting up a prescription safety eyewear program is the choice of lens material. Safety lens choices have increased over the past few years and are offered in several materials: Trivex, Polycarbonate, CR-39 Plastic, and High Index Plastic.

Shannon Optical strongly recommends the use of Trivex or Polycarbonate Lens Material.

Trivex:

- High Impact resistance rating per ANSI Z87.1

- 60 times more impact resistant than standard plastic

- Twice as scratch resistant as polycarbonate

- Provides 100% UVA and UVB protection

- Temperature resistant

- The lightest lens material available today

- Tough against harsh chemicals and solvents which typically crack polycarbonate lenses

Polycarbonate:

Polycarbonate lenses are thinner and lighter than regular plastic lenses.

- Impact Resistant

- Lightweight

- Provides UV Protection

CR-39 Plastic:

- First polymer lens that replaced glass

- Less prone to shattering

- Can be tinted to provide glare protection

High Index:

- Designed for higher prescription ranges

- Thinner than polycarbonate

Why Shannon Optical?

For over 60 years, Shannon Optical has provided prescription safety eyewear programs to industry workers nationwide. We work directly with your business to create personalized programs to outfit your workers for the maximum in design, fit, and safety.

Our goals? To provide you with a premium safety glass program, to ease your administrative Compliance burdens, and to guarantee your complete satisfaction – all while fitting into your company’s budget.

Our customer base spans the entire United States. No matter the size and location of your business or its eyeglass needs, our wide range of products and services can meet them all!